Source: newatlas.com

Published: February 5, 2016

There’s aerogel in that thar paper Shutterstock

By Ben Coxworth

Known as “frozen smoke” because of their milky translucent appearance, aerogels are among the world’s lightest solid materials. Consisting of 99.8 percent air, they’re highly heat-resistant and are an excellent form of insulation. Now, scientists at the National University of Singapore (NUS) have used paper waste to create one.

Previously, aerogels have been made mainly from silica, along with substances such as metal oxides, polymers, carbon nanotubes and graphene. The NUS technique is claimed to be considerably more environmentally-friendly, however, using less power, releasing less toxic emissions, and requiring less hazardous chemicals – plus it uses a material that might otherwise go into the landfill.

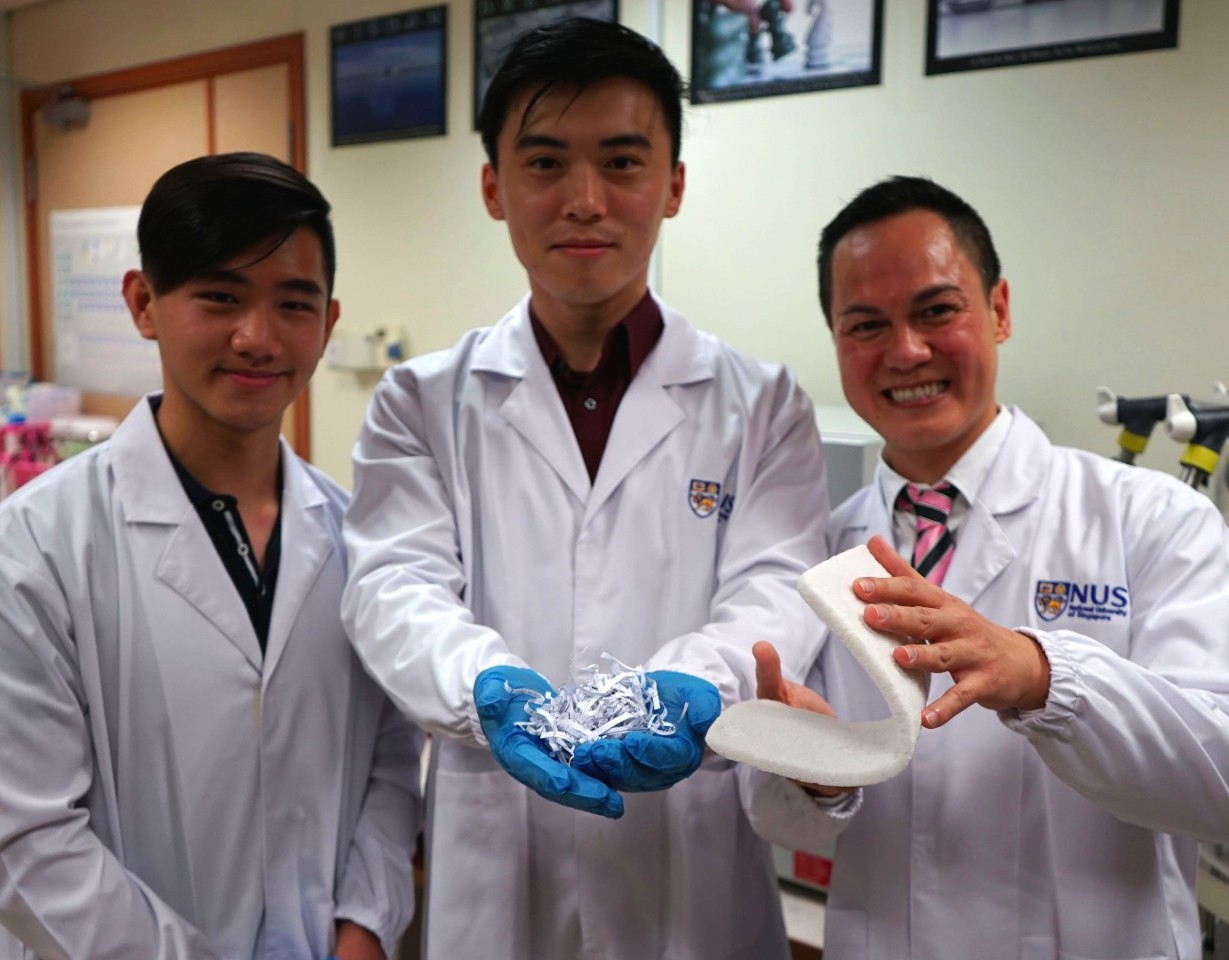

Assistant Professor Duong Hai Minh (right) holds a sample of the cellulose aerogel which he developed with his team members, Gu Bowen (centre) and Siah Jie Yang (left) who are both undergraduate students from the Department of Mechanical Engineering (Credit: National University of Singapore)

The “cost-effective” production process begins by mixing water with cellulose fibers, the latter obtained by mulching the paper. A cross-linking polymer resin is then added to the mixture, after which it’s sonicated – sonication is the process of using sound energy to agitate particles in a solution.

Next, the mixture is poured into molds and frozen at -18º C (0º F) for 24 hours, after which it’s freeze-dried at -98º C (-144º F) for two days. Finally, it’s cured in an oven at 120º C (248º F) for three hours. The final result is an opaque biodegradable material that is non-toxic, flexible, mechanically-strong and oil-absorbent.

When coated in methyltrimethoxysilane (MTMS), the cellulose aerogel becomes very hydrophobic (water-repelling). This means that if it were placed in an oil spill, it could soak up as much as 90 times its dry weight in crude oil, without “filling up” on water. It could then be wrung out like a sponge, allowing over 99 percent of the absorbed oil to be recovered.

The material could also find use as wall insulation in buildings. Besides keeping heat contained within the structure, it would resist moisture buildup, add strength to the walls, and take up less space than traditional materials such as fiberglass wool. It might likewise be used as a form of protective packaging, or in wound-plugging medical sponges. When doped with metallic nanoparticles and hammered flat to remove its air content, the aerogel can additionally be converted into a mechanically-strong thin magnetic film.

If not coated in MTMS, the highly-porous aerogel does absorb water and other liquids, allowing for its use in products such as diapers or sanitary napkins.

The technology is being commercialized by materials company Bronxculture.

Source: NSU