Source: worldcoal.org

Published: January 26, 2017

Carbon capture, use and storage technology will be key to reducing global CO2 emissions, not only from coal, but also natural gas and industrial sources.

To discover more about the pathway towards zero emissions coal, download our ‘Driving CCUS Deployment: The Pathway to Zero Emissions from Coal’ report or learn about how the technology works below.

Driving CCUS Deployment – the pathway to zero emissions from coal

Carbon capture, use and storage (CCUS) is an integrated suite of technologies that has a proven 90% capture rate of the CO2 produced from the use of fossil fuels in electricity generation and industrial processes, preventing the CO2 from entering the atmosphere. Looking ahead, scope exists for future CCUS projects to have much improved capture rates, including zero-emissions from coal.

Capture

Capture technologies allow the separation of CO2 from gases produced in electricity generation and industrial processes by one of three methods:

- Pre-combustion capture

- Post-combustion capture

- Oxyfuel combustion

Transportation

CO2 is then transported for safe use or storage. Millions of tonnes of CO2 are already transported annually for commercial purposes by pipelines, ships and road tanker. The US has four decades of experience of transporting CO2 by pipeline for enhanced oil recovery projects.

IN SUMMARY:

- CCUS technologies

- Use and storage

- CCUS costs

- CCUS today

- Petra Nova CCUS project

- Boundary Dam CCUS project

Photo: SaskPower’s Boundary Dam CCUS project

Use and storage

Use

CO2 can be used as a value-added commodity. This can result in a portion of the CO2 being permanently stored – for example, in concrete that has been cured using CO2 or in plastic materials derived from biomass that uses CO2 as one of the ingredients. The CO2 can also be converted into biomass. This can be achieved, for example, through algae farming using CO2 as a feedstock. The harvested algae can then be processed into bio-fuels that take the place of non-biological carbon sources.

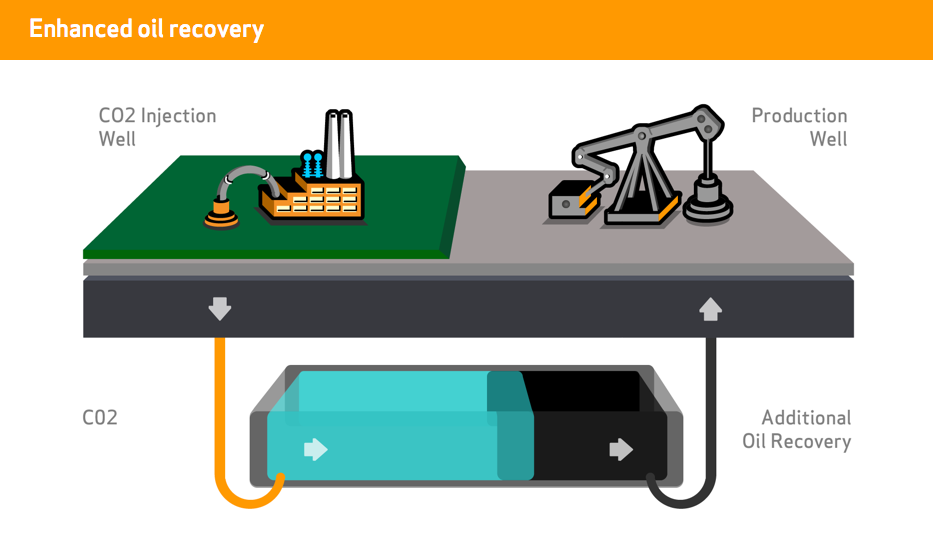

Enhanced oil recovery

CO2 is already widely used in the oil industry for enhanced oil recovery (EOR) from mature oilfields. When CO2 is injected into an oilfield it can mix with the crude oil causing it to swell and thereby reducing its viscosity, helping to maintain or increase the pressure in the reservoir. The combination of these processes allows more of the crude oil to flow to the production wells. In other situations, the CO2 is not soluble in the oil. Here, injection of CO2 raises the pressure in the reservoir, helping to sweep the oil towards the production well. In EOR, the CO2 can therefore have a positive commercial value and can help support the deployment of CCUS and create a revenue stream for CCS projects, as the CO2 captured becomes an economic resource.

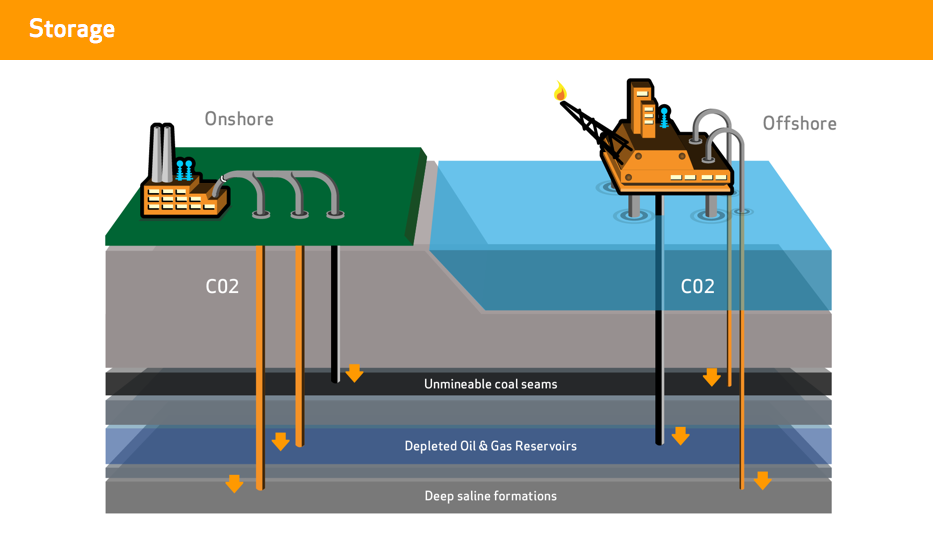

Storage

CO2 is stored in carefully selected geological rock formations that are typically located several kilometres below the earth’s surface. As CO2 is pumped deep underground, it is compressed by the higher pressures and becomes essentially a liquid. There are a number of different types of geological trapping mechanisms (depending on the physical and chemical characteristics of the rocks and fluids) that can be utilised for CO2 storage.

At every point in the CCUS chain, from production to storage, industry has at its disposal a number of process technologies that are well understood and have excellent health and safety records. The commercial deployment of CCUS will involve the widespread adoption of these CCUS techniques, combined with robust monitoring techniques and government regulation.

“The IEA has estimated that CCUS could deliver 14% of cumulative GHG emissions cuts through to 2050 and that climate change action will cost an additional US$4.7 trillion without CCUS”

CCUS costs

All the options for capturing CO2 from power generation have higher capital and operating costs as well as lower efficiencies than conventional power plants without capture. Capture is typically the most expensive part of the CCS chain. However, as CCS and power generation technology become more efficient and better integrated, the increased energy use is likely to fall significantly below early levels. Much of the work on capture is focused on lowering costs and improving efficiency as well as improving the integration of the capture and power generation components. These improvements will reduce energy requirements.

EOR can also help support the deployment of CCUS and create a revenue stream for CCS projects as the CO2 captured becomes an economic resource.

CCUS today

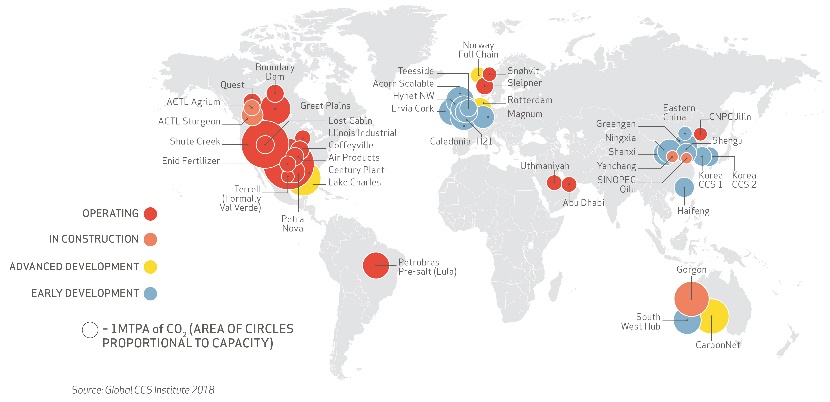

To date, there are a total of 51 large-scale CCS facilities globally – 19 in operation, 4 under construction, and 28 in various stages of development. Together, the 51 facilities have an estimated capture capacity of around 96 million tonnes of CO2 per annum.

Significant projects include:

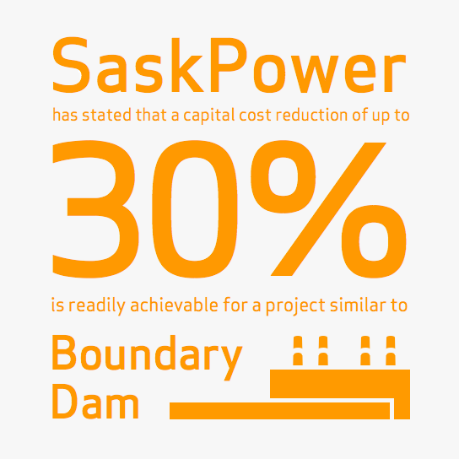

Boundary Dam power station

The world’s first large-scale CCS project in the power sector commenced operation in October 2014 at the Boundary Dam power station in Saskatchewan, Canada.

Petra Nova

Petra Nova, which came online in early 2017 and is the second CCUS coal plant, is the world’s largest post-combustion carbon capture facility installed on an existing coal-fuelled power plant and plans to store more than 1.6 million tonnes of CO2 a year.

The Sleipner and Snøhvit CO2 storage projects

These projects in Norway have stored over 16 million tonnes of CO2 into offshore deep saline formations.

Abu Dhabi CCS Project

The project came online in 2016 and is the world’s first commercial CCUS facility for the steel industry, capturing 800,000 tonnes of CO2 and, injecting it in maturing fields to enhance oil recovery (EOR)

Tuticorin CCU Project

The unsubsidised, fully commercial CCUS project from Carbon Clean Solutions in the port of Tuticorin, India has been able to significantly reduce the costs associated with capturing the CO2

Role of CCUS in global climate action

CCUS is an important option in global efforts to reduce CO2 emissions. Research from the Intergovernmental Panel on Climate Change (IPCC) has shown that climate action will be 138% more expensive without carbon capture and storage and that meeting the 2°C target could actually be impossible without it.

A map of CCUS projects worldwide is available on the Global CCS Institute website.

Petra Nova CCUS project

Petra Nova is a post-combustion, coal-fuelled CCUS facility that reduces carbon dioxide emissions by 90%. The Texan power plant has been operational since 2016 and the project was completed on-budget and on-time.

Petra Nova captures CO2 from a 240 MW slipstream of flue gas from WA Parish Unit 8. The captured CO2 is then injected into mature oil reservoirs in order to boost oil production. Within the first ten months of operation, the project boosted oil recovery by 1300%.

Petra Nova captures 5000 metric tonnes of CO2 every day, which is the equivalent of taking 350,000 cars off the road.

Boundary Dam CCUS project

The Boundary Dam Project sees the integration of a rebuilt coal-fired generation unit with carbon capture technology, resulting in low-emission power generation. Launched in 2014, the project is the world’s first post-combustion coal-fired CCS project.

The project transforms the aging Unit #3 at Boundary Dam Power Station near Estevan, Saskatchewan into a reliable, long-term producer of 115 megawatts (MW) of base-load electricity and reduces greenhouse gas emissions by one million tonnes of CO2 each year. That’s equivalent to taking more than 250,000 cars off Saskatchewan roads annually.

The captured CO2 is transported by pipeline to nearby oil fields in southern Saskatchewan where it is used for enhanced oil recovery. CO2 not used for enhanced oil recovery is stored in the Aquistore Project.

In addition to CO2, there are opportunities for the sale of other byproducts from the project. Sulphur dioxide (SO2) will be captured, converted to sulphuric acid and sold for industrial use. Fly ash, a by-product of coal combustion, will also be sold for use in ready-mix concrete, pre-cast structures and concrete products.