Source: citylab.com

Published: May 19, 2016

Mark Byrnes, Flickr/Jason Lawrence, Paul Sullivan, NYbuspics

Personal cars get most of the attention, but trucks and buses are long overdue for an efficiency upgrade.

When it comes to cleaning up automotive emissions, Tesla gets all the love. The upstart automaker garners the headlines and praise for making electric driving not just feasible, but sexy. That’s important, but all the attention on innovations for personal cars misses one critical fact: The cars most people drive each day are already among the most fuel-efficient vehicles on the road. Meanwhile, the real emissions offenders—buses, delivery trucks, dump trucks, long-haul trucks—have managed to avoid much improvement over the years.

“The thing about modern cars is, they’re so incredibly clean already, that it’s hard to make them any better,” says automotive engineer and entrepreneur Ian Wright, who co-founded Tesla but left in 2005 to focus more on the dirtiest vehicles.

Transportation emissions make up 26 percent of all greenhouse gases in the U.S., according to the Environmental Protection Agency. Smaller vehicles like personal cars, SUVs, and pickups, account for 60 percent of those emissions. (That’s why the most effective way for individuals to cut their emissions is to improve their own driving habits.)

Meanwhile, medium- and heavy-duty trucks produce 23 percent of all transportation emissions in the U.S. even though they only make up 5 percent of all vehicles on the road. Buses fall into a miscellaneous category that amounts to 4 percent of transportation emissions. There are far fewer of these carbon-heavy vehicles, but their efficiency is ridiculously low—around 7 mpg on average, lower for certain kinds of truck. That means even small improvements in the most-polluting vehicles can have a big effect on overall emissions.

Cutting those emissions from transport is necessary for any vision of a society that doesn’t pump dangerous amounts of carbon into the atmosphere. Now, a growing community of engineers and entrepreneurs is tackling the challenge of fuel efficiency among the dirtiest vehicles, and they’re getting results. To complete the transition to a low-carbon society, policymakers will need to encourage and implement innovations to address these major causes of pollution.

Buses

Diesel buses anchor the team for most transit systems, but they’re not the cleanest things to have around. They’re loud, smelly, and pump carcinogenic particles into the air. Because they sell to large institutional buyers, the industry has been buffered from consumer trends, but that’s starting to change.

Cleaning up the bus sector starts with a change in manufacturing processes. These vehicles are “a hand-me-down from the truck industry,” says Ryan Popple, CEO of electric bus company Proterra. Conventional bus makers use heavy metal chassis with lots of rivets and steel, and rely on diesel engines produced for the trucking industry.

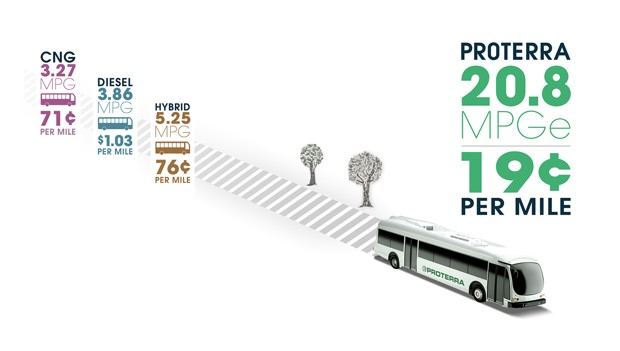

(Proterra)

“A bus in a lot of ways is a truck that’s been optimized to carry human beings,” Popple says. “The problem with that is trucks are more efficient when they’re on the open road at a constant RPM, whereas in the duty cycle of an urban bus it starts and stops 500 times in a single day.”

The engineers at Proterra rebuilt the bus from scratch using a lightweight composite chassis powered by lithium ion batteries. This lightness helps the buses achieve fuel efficiency equivalent to more than 20 miles per gallon. They also come with active safety features and wireless internet built in. And since there are so few moving pieces, minimal excess heat, and little material at risk of rusting, the maintenance costs come way down compared to diesel.

The price has been falling, too. Five years ago an electric bus cost $1 million and diesel was $450,000. Now Proterra’s basic model sells for $749,000, comparable to a hybrid-diesel bus. And, Popple notes, a growing number of jurisdictions don’t allow pure diesel buses anymore due to air quality concerns. When you calculate lifetime costs (vehicle plus fuel and maintenance), diesel comes to $1.4 million and an EV bus is $1 million, he says.

Of course, the cost benefit analysis doesn’t work unless the transit agency has an easy way to recharge the buses’ batteries.

“The operators don’t want transit vehicles sitting still, charging,” Popple says. “When a transit vehicle’s moving, they’re making money.”

(Proterra)

The new Extended Range model can go 194 miles on a single charge, which covers a lot of daily bus routes. There’s also a backup plan: bus routes typically have a layover point where the driver pauses at the end of each cycle; this allows some buffer in the schedule for variations in drive time. Proterra designed an overhead charging station that goes in at that layover point and can fill up the Fast Charge Model’s 100 kilowatt-hour battery in just 12 minutes.

“In the long run, it’s possible that electric vehicles are more useful in transit than diesel vehicles, because theoretically you’d never take the vehicle back to a fueling barn,” Popple says, adding that, for olfactory reasons, it would be best to at least stop for cleaning every 24 hours or so.

This company serves as proof of concept that electric buses can work—16 different transit agencies have purchased a total of 155 vehicles from Proterra, and the company is working through an 18-month backlog of orders.

Urban trucking

While buses carry people through the city, a diverse fleet of trucks delivers and picks up just about everything else: garbage, packages, beer. These heavy vehicles don’t have the same kind of route predictability that allows Proterra to recharge batteries at key points. Until battery technology improves, then, they’ll need to look elsewhere to boost efficiency.

Wright, the engineer, thinks he’s found one. His company, Wrightspeed, produces electric drivetrain range extenders for trucks. Once installed, the truck runs on electricity, which is much more efficient than internal combustion, and captures energy each time the vehicle brakes. When the battery runs out, a highly efficient gas turbine kicks in to recharge it. The turbines burn fuel much more efficiently than a traditional piston engine, resulting in fewer nasty emissions. Compared to the national average of 2 to 3 mpg for a diesel garbage truck, this system runs around 6 mpg.

The company is still ramping up production. After a two-truck trial run, FedEx ordered 25 delivery trucks with the electric drivetrain in 2014. Wrightspeed also signed a deal with NZ Bus, the biggest city bus operator in New Zealand. It’s too early to know if it will catch on, but one factor in favor of this technology is its self-containment: the drivetrain doesn’t require any capital-intensive infrastructure to keep the vehicles running. Companies or municipalities just need to pay for a one-time conversion or buy new trucks with the drivetrain, and that’s it.

Long-distance trucking

Long-haul trucks carry the weight of modern commerce on their backs. They handle 70 percent of freight in the U.S. by weight, twice as much each year as all other transportation modes combined. The problem, as far as the climate is concerned, is that they’re not very efficient and they’re terrible candidates for electrification.

Shipping companies need trucks to cover hundreds of miles with minimal stops, and that’s something hydrocarbon fuel does really well. A full diesel tank can carry a truck 1,500 miles or more; a fully charged Tesla Model S can run about 270 miles, and that’s a super-light passenger car. Right now, electric really isn’t on the table for long-distance trucking, says John Woodrooffe, a large vehicle efficiency expert at the University of Michigan Transportation Research Institute.

Wrightspeed CEO Ian Wright explains the technology behind his electric-powered engine at the company’s headquarters in San Jose , Calif. (AP Photo/Marcio Jose Sanchez)

“You’d probably have to fill the whole doggone truck up with batteries, quite literally, without being able to move any cargo,” he says. “What we’ve found is that the energy density in diesel fuel is very hard to replicate in any substitute fuel.”

Even if major innovations in battery technology came along, the industry would have to be persuaded to swap out several million trucks and build a continent-wide charging infrastructure. And then the power grid would have to be ready to handle it all. That electricity would need to come from clean sources in order for the electrified transport to actually eliminate emissions.

For now, progress on heavy trucks will mean eking every last bit of efficiency out of internal combustion vehicles, by optimizing everything from driving behavior to aerodynamics. The EPA is working on new efficiency standards to do just that. Adding up all the different technologies available now, incremental improvements could lead to fuel savings of around 40 percent, says Rachel Muncrief, heavy duty vehicle program lead at the International Council on Clean Transportation.

The Obama administration proposed tougher mileage standards for medium and heavy-duty trucks in 2015. (AP Photo/Susan Walsh)

Drivers can take a more targeted approach to fuel economy with new tools like Headwind Hunter, an app that advises drivers based on real-time wind conditions in their area. Creator Matthew Merzig, president of Aerodynamic Applications, says if drivers use his program to ride a tailwind and ease off the gas when winds are against them, they can save 1 to 3 percent on fuel economy annually. For independent truckers who spend on average $50,000 to $60,000 in fuel costs each year, that adds up.

The advent of automated driving holds an alluring possibility: platooning. Automated driving could be so precise that trucks form a tight line, bumper to bumper, at high speeds, which significantly decreases drag. It’s the freight equivalent of cyclists drafting in a race, or geese flying in a V. The underlying technology for vehicle to vehicle communication is largely proven, says Zach Barasz, who invests in transportation technology companies at Kleiner Perkins Caufield and Byers’ Green Growth Fund.

“There’s nothing magical about the technology side—it’s a matter of building out a system that’s durable to every single corner case,” he says. “You can’t be 99.9 percent right. You need a couple more nines.”

It’ll be a while, then, before this is safe enough for prime time.

Change the truck

Uniform design changes across the trucking industry are problematic, Muncrief says, because every truck is customized for its particular job. New designs have to be sensitive to the array of commercial uses that trucks perform, or they could drive a lot of people out of business.

Certain efficiency gains are also happening in tire design to reduce rolling resistance and truck design to reduce drag. A study by Woodrooffe notes that radical redesign of trucks and trailers could theoretically cut 42 percent of aerodynamic drag, but that kind of overhaul is unlikely in the near-to-middle-future. Simpler additions, like adding skirting along the sides and back of trucks to reduce wind resistance, could improve fuel efficiency by 10 percent.

“We have international markets and free trade at the moment because transportation costs permit that.”

The government could achieve much greater efficiency, Woodrooffe says, by modernizing the regulations that govern truck size and weight. Canada, for instance, allows shipping trucks up to 137,500 pounds, compared to the U.S. upper limit of 80,000. Big Canadian trucks deliver twice as much cargo with 68 percent less fuel use and emissions than the largest trucks allowed in the U.S. Canada has also shown that, with the right policies, bigger trucks don’t have to be more dangerous.

“We have a [size and weight] policy that dates back to around 1980, that’s the last time we really revised it,” Woodrooffe says. “Every other country has had reform within size and weight over the past 30 years, usually on a fairly regular basis. We’re in the dark ages, really.”

Adopting evidence-based regulations for bigger truck capacity, he says, means the U.S. could get its shipping done with fewer vehicles, and that’s better for the environment and for safety. Improving individual fuel economy will help, but the big picture strategy needs to focus on emissions per cargo ton-mile; that is, how much carbon a truck burns to carry a certain amount of freight a certain distance.

This evolution won’t happen in a vacuum. As Woodrooffe points out, how humans move freight around gets at some really fundamental principles of how societies are organized. “We have international markets and free trade at the moment because transportation costs permit that,” he says. “If transportation costs were high, or transportation was unavailable, then that option wouldn’t exist.” These shipping practices helped create climate change; now, to maintain a climate that allows trade to flourish, humanity will need to find a new way to move things around.

Elements from top illustration via Jason Lawrence, Paul Sullivan, and NYbuspics under a Creative Commons license.